Our Services

What Our Clients Have To Say

Always Seek The Opportunity

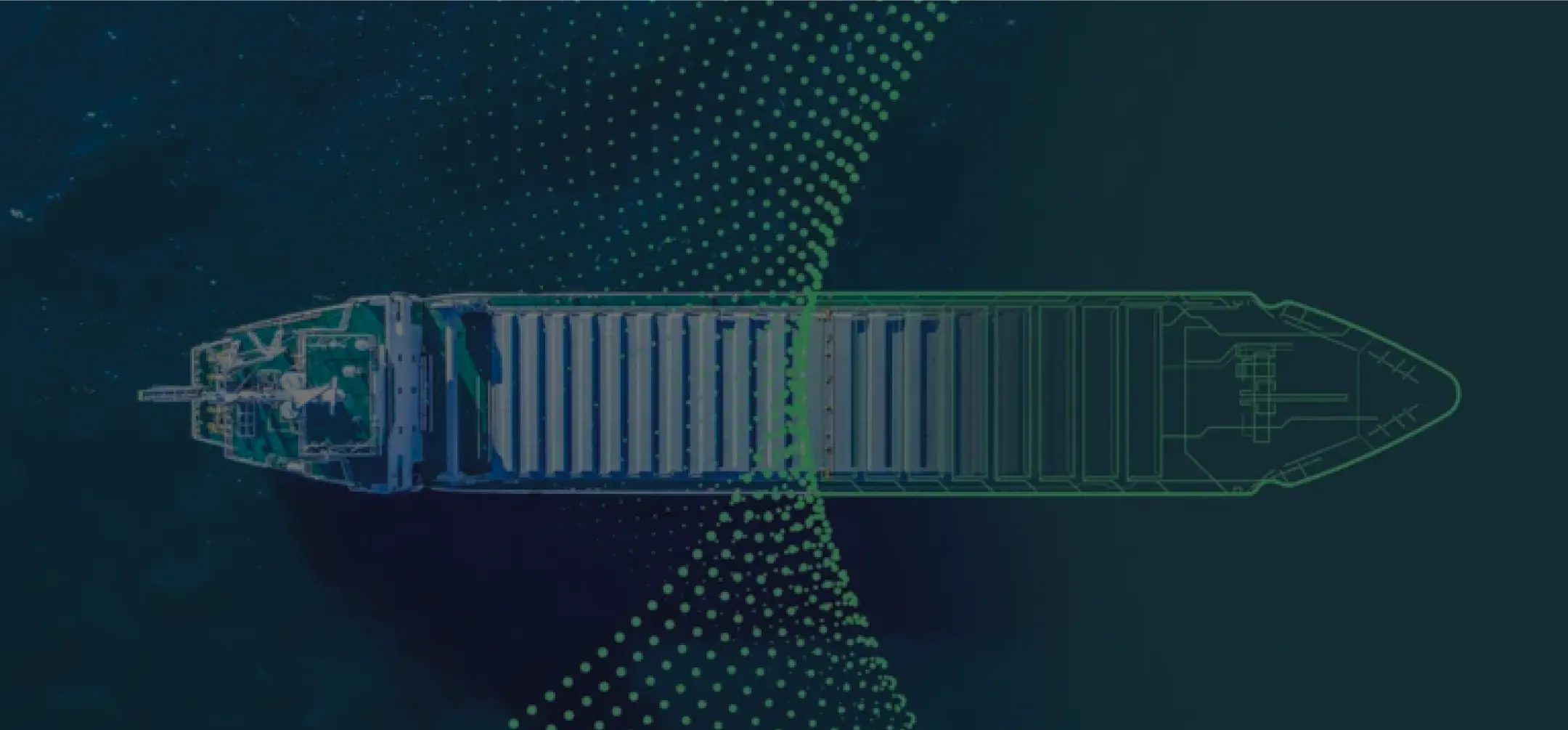

What’s The Problem?

A vessel company struggled with inconsistent PMS data, leading to inefficiencies, compliance risks, and rising costs. Unstandardised job codes and duplicated tasks resulted in wasted resources, while lack of proactive maintenance caused frequent errors. Without structured data management, decision-making suffered, and operational downtime increased.

Our Solution

PiscesER1 Marine implemented a PMS Data Maturity Model, achieving 25.2% savings in time and cost through vessel similarity analysis. With proactive maintenance and a 16x5 support system, we streamlined job scheduling, reduced audit non-conformities by 125 hours, and saved $15,000 per vessel by preventing machinery breakdowns. Over five years, optimised PMS data improved reliability, efficiency, and cost control.